Understanding Tooling Molds: A Comprehensive Guide for Metal Fabricators

The manufacturing industry continually seeks ways to enhance efficiency and reduce costs, especially in metal fabrication. One critical component that contributes to achieving these goals is the tooling mold. This article will delve into the world of tooling molds, exploring their significance in metal fabrication, the various types available, and the processes involved in their production.

What is a Tooling Mold?

A tooling mold serves as a template that defines the shape and details of a product. Primarily used in metal fabrication, tooling molds allow manufacturers to produce components or parts with high precision and in mass quantities.

Tooling molds are crafted from durable materials, often metals or robust plastics, capable of withstanding the rigors of repeated use. They play an instrumental role in various industries, including automotive, aerospace, and consumer goods.

The Importance of Tooling Molds in Metal Fabrication

Tooling molds are indispensable in achieving numerous manufacturing objectives:

- Precision and Accuracy: Tooling molds ensure that every product meets strict tolerances. This precision minimizes waste and maximizes material usage.

- Cost Efficiency: By enabling mass production, tooling molds help reduce the cost per unit, benefiting businesses financially.

- Consistency: Tooling molds facilitate the consistent production of identical parts, crucial for industries where uniformity is paramount.

- Complex Designs: They allow manufacturers to create complex shapes that would be cumbersome or impossible to achieve through other methods.

- Speed of Production: Tooling molds streamline the manufacturing process, leading to quicker turnaround times and improved productivity.

Types of Tooling Molds

Understanding the various types of tooling molds is essential for metal fabricators. Each type is suited for specific applications:

1. Injection Molds

Injection molds are used to create parts by injecting molten material into a mold cavity. This technique is widely utilized for thermoplastics and can produce high volumes of identical parts.

2. Blow Molds

Blow molds involve inflating hot plastic within a mold to form hollow shapes. This is commonly used for creating containers like bottles and jars.

3. Compression Molds

Compression molds operate by placing a material into a heated mold, where it is then compressed and cured. This method is prevalent in producing rubber and certain plastics.

4. Rotational Molds

Rotational molding involves rotating a mold around a central axis while heating the material inside. This method is effective for producing large, hollow parts.

5. Die Casting

Die casting is notable for its ability to produce complex shapes in metal, typically aluminum and zinc, through high-pressure injection into a mold cavity.

The Tooling Mold Manufacturing Process

Producing a tooling mold entails several steps, each critical in ensuring the final product meets the required specifications:

1. Design and Engineering

The first step in creating a tooling mold is the design phase. Engineers use computer-aided design (CAD) software to develop a detailed blueprint of the mold, ensuring that it aligns with the desired specifications of the part to be produced. Factors such as material specifications, cooling channels, and ejection mechanisms are considered during this phase.

2. Material Selection

Choosing the right material is paramount. The material for the mold must be durable enough to withstand the pressures and heat of manufacturing processes. Common materials include hardened steel, aluminum, and certain high-performance plastics.

3. Prototyping

Creating a prototype of the tooling mold can help identify potential issues before full-scale production. This step allows engineers to test the design's functionality and make adjustments as necessary.

4. Fabrication

The fabrication process involves machining the selected material into the desired shape. Techniques such as CNC machining, electrical discharge machining (EDM), and grinding are commonly employed to produce the mold with high precision.

5. Finishing Processes

After fabrication, molds go through finishing processes that enhance their surface quality. This may involve polishing, heat treatment, or coating to increase durability and reduce friction during production.

6. Testing and Quality Assurance

Before a tooling mold is deemed ready for production, it undergoes rigorous testing. Quality assurance measures ensure the mold executes its intended function according to the design specifications.

Challenges in Tooling Mold Production

While it offers numerous benefits, the production of tooling molds comes with its challenges. Being aware of these challenges can aid metal fabricators in preparing for and mitigating potential risks:

- High Initial Costs: The upfront investment for tooling mold production can be significant due to design, material, and manufacturing costs.

- Long Lead Times: Creating precision molds is a time-consuming process, and delays in design or fabrication can hinder project timelines.

- Maintenance and Repair: Over time, molds can wear down or become damaged, necessitating maintenance and repair, which can further complicate production schedules.

- Material Limitations: Not all materials are suited for every application, and selecting the wrong material could lead to poor performance or product failures.

The Future of Tooling Molds in Metal Fabrication

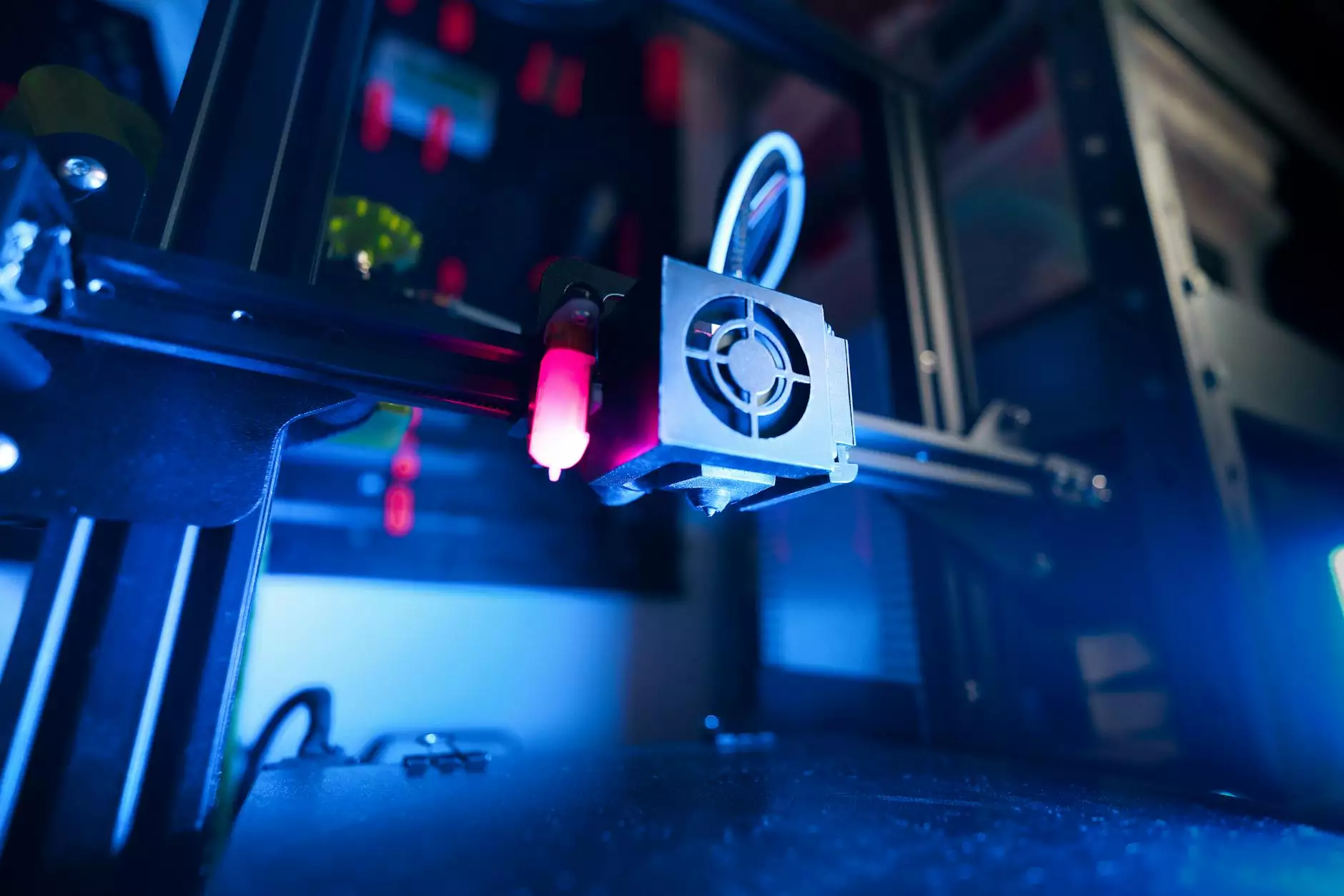

As technology progresses, the future of tooling molds appears promising. Innovations such as 3D printing and advanced materials are significantly influencing the mold-making process:

- Additive Manufacturing: This technology allows for faster prototyping of molds, reducing lead times and costs. It also enables the creation of complex geometries that traditional methods may find challenging.

- Smart Manufacturing: Integration of IoT (Internet of Things) can enhance monitoring and maintenance of molds, leading to predictive maintenance and improved overall efficiency.

- Sustainable Practices: As industries migrate toward sustainability, molds are being developed from recycled materials, contributing to greener manufacturing processes.

Conclusion

In conclusion, tooling molds are a fundamental aspect of metal fabrication, offering a myriad of advantages that facilitate efficient and cost-effective production. Understanding the different types of molds, the manufacturing process, the associated challenges, and the advancements in technology can empower metal fabricators to leverage tooling molds effectively. For companies like Deep Mould, embracing these insights will be key to remaining competitive in the evolving landscape of manufacturing.

By strategically investing in high-quality tooling molds and embracing innovation, businesses can set themselves apart, driving growth and success in their respective industries.